In an era where the safe and compliant transportation of sensitive materials is critical—from medical specimens to hazardous chemicals—95kPa transport bags have emerged as a cornerstone of secure logistics. These specialized packaging solutions are engineered to meet rigorous international standards, ensuring integrity under pressure and extreme conditions. Here’s a comprehensive guide to their applications, compliance requirements, and innovations shaping the industry.

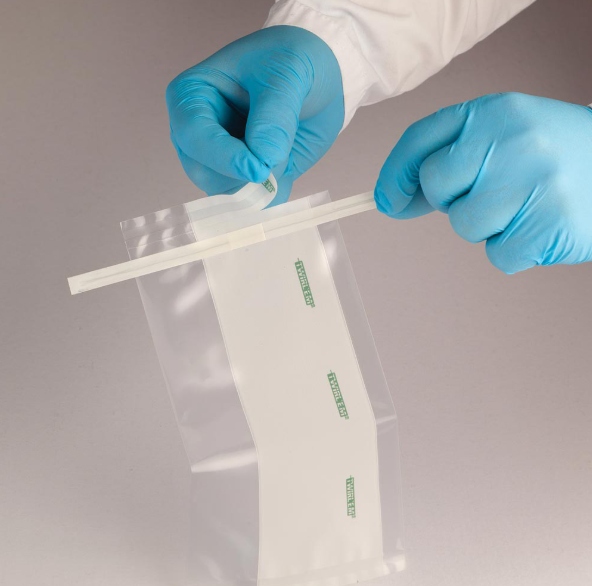

What Are 95kPa Transport Bags?

95kPa transport bags are high-performance packaging systems designed to withstand internal pressure changes up to 95 kilopascals (kPa), equivalent to approximately 13.8 psi. This pressure resistance is vital for air transport, where cargo holds experience significant altitude-related pressure fluctuations. Key features include:

- Triple-layer construction: Typically made from puncture-resistant polyethylene, nylon, or polypropylene.

- Leak-proof seals: Heat-sealed edges and airtight closures to prevent contamination.

- UN certification: Compliance with United Nations standards for dangerous goods packaging (e.g., UN 4G/Y95/S).

These bags are indispensable for industries requiring adherence to IATA (International Air Transport Association) and ADR (European Agreement Concerning the International Carriage of Dangerous Goods by Road) regulations.

Key Applications

1.Medical and Pharmaceutical Logistics

Transporting biological samples (blood, tissues), vaccines, and diagnostic kits.

Essential for maintaining cold chain integrity during global distribution.

2.Hazardous Material Handling

Safe containment of chemicals, flammable liquids, and radioactive materials.

Widely used in laboratories, manufacturing, and environmental cleanup.

3.E-commerce and Specialty Goods

Protecting sensitive electronics, aerospace components, and high-value artifacts from pressure damage.

Compliance and Certification

To ensure safety and legality, 95kPa bags must meet stringent certifications:

- IATA DGR 65: Mandatory for air transport of Category B biological substances.

- UN 4G/Y95/S: Validates pressure resistance and durability.

- ISO 9001: Quality management standards for manufacturing consistency.

How to Choose the Right 95kPa Transport Bag

1.Material Durability: Opt for tear-resistant, temperature-stable fabrics for extreme climates.

2.Size and Capacity: Match inner dimensions to cargo volume (common sizes range from 5L to 100L).

3.Sealing Mechanism: Check for double-sealed zippers or adhesive strips for airtight security.

4.Sustainability: Biodegradable options are gaining traction among eco-conscious industries.

Innovations Driving the Market

- Smart Tracking Integration

RFID tags and IoT-enabled sensors now monitor real-time pressure, temperature, and location.

- Eco-Friendly Materials

Brands like EcoSafePak are pioneering 95kPa bags made from recycled ocean plastics.

- Customizable Solutions

On-demand printing for hazard labels, handling instructions, and corporate branding.

Market Outlook

The global transport packaging market, valued at $30.2 billion in 2023, is projected to grow at a 6.8% CAGR through 2030, driven by rising biopharma exports and stricter safety regulations. Australia, a hub for medical research and mining, has seen a 15% annual spike in demand for compliant 95kPa solutions.

Case Study: Securing Vaccine Distribution

During the COVID-19 pandemic, MediLogix Australia leveraged 95kPa bags with phase-change materials (PCMs) to ship Pfizer-BioNTech vaccines across remote regions. The bags maintained temperatures between -70°C and -20°C, achieving a 99.8% delivery success rate.